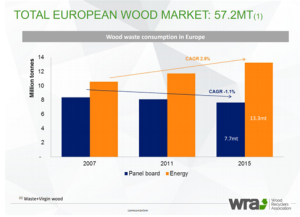

Wood is a versatile raw material that can be used for various applications in the paper, packaging, furniture, housing and other sectors. According to a Parliament briefing, in 2012 52.9 million tons of wood waste were produced in the EU. Construction and demolition waste (CDW) accounts for approximately 25% – 30% of all the waste generated in the EU. Depending on its quality, wood waste can be either recycled, used for energy, or disposed of in landfills. In 2015, about 13.3 million tons of wood waste were used for energy and 7.7 million tons were recycled for the manufacturing of panel boards (source: Wood Recyclers Association UK). The level of recycling varies significantly among the European Member States, therefore, identifying and applying good practices from the most virtuous states can effectively help the least virtuous ones to increase their recycling rates

Legislation and classification are key drivers for market and trade

While a decade ago most wood waste was reused and recycled locally, today significant volumes are shipped across Europe. Wood waste is a common feedstock for bioenergy plants in Germany, UK, The Netherlands, Sweden, Belgium and France. The main importers of both hazardous and non-hazardous wood waste are Germany and Sweden (more than 600 kton/y), while the UK, The Netherlands and Norway are the main exporters (Source: IEA Bioenergy Task 40). Regarding UK, the trend is reversed with the commissioning of facilities following the voluntary policy of developing this type of energy source. The trade of non-hazardous wood waste is increasing since 2010, because of its industrial grade nature and cheaper price than other biomass resources. On the other hand, hazardous wood waste shipments are showing a declining trend due to stricter legislation.

Clear legislation and classification of wood waste are key drivers for the valorisation of wood waste and in order to make trade possible, many European states have developed classification systems, although a common harmonized system at EU level is not available yet. The energy sector and the particleboard manufacturing industry are sometimes competing for the supply of this resource, although their quality requirements can be different. Both of the sectors require high quality wood waste with no pollutants, the energy sector can afford the use of relatively lower quality wood waste by deploying effective gas treatment systems that ensure the recovery of chlorine, metals and other contaminants. The panel industry is interested more in the physical quality of wood waste, preferring solid wood in its supplies. Solid wood comes mainly from buildings (construction and demolition) and contains more pollutants than the waste wood from furniture (mainly reconstituted wood).

BIOREG: unlocking the potential of wood waste in the EU

Absorbing the potential of wood waste in EU regions and industrial biobased ecosystems is the objective of BIOREG, a Horizon 2020 project launched in 2017 with the aim to identify and unlocking the potential of unused wood waste by promote a full range of valorisation practices among European regions. For this purpose, five model regions were analysed, and three recipient regions are engaged in replication of good practices. Demonstrator case studies were selected in regions which have set up renewable wood waste-based systems at different stages of the value chain including different wood waste sources, pre-sorting, sorting, collection, recycling and wood waste treatment. These were identified in Gothenburg (Sweden); Baden- Wurttemberg (Germany); Lombardy (Italy), North West England (UK), Vorarlberg and Styria (Austria). Three recipient regions were selected: Normandy (France), Lubelskie (Poland) and Alentejo and Lisboa (Portugal).

In 2017 BIOREG partners had the opportunity both to organize projects events and to participate in seminars and conferences. The purpose of all BIOREG events and initiatives was to discuss different practices, highlighting the national and European landscape and obstacles to valorise wood waste in EU regions, to bring together all relevant stakeholders, in order to deeply analyze the situation and propose solutions. Local events were organized in Portugal: meetings with regional authorities in Caparica, in Estremoz and Alentejo, and with the wood recycling associations in Porto. In Poland, a workshop was organized in Pulaway to share best practices. The same year in November, BIOREG was also presented to industrial stakeholders during a seminar dedicated to wood waste in Le Havre Normandy.

In 2018 BIOREG was presented to the members of ECIRBEN in Normandy, France. The objective of the ECIRBEN programme was to quantify and qualify the physico-chemical and thermo-chemical aspects of wood waste from Normandy and Ile-de-France in order to define local recovery scenarios. Other meetings were organized again in Covilhâ (Portugal) and in Elenite (Bulgaria), with stakeholders from Bulgaria, Romania and Hungary. In the same year, BIOREG was also featured at the Bioeconmy Stakeholders Panel in Brussel.

In 2019 partners continued networking and interacting with regional stakeholders in France at the Assembly of the national wood sector strategic committee, in Poland at the LUBDREW Woodworking Fair and in Portugal, first with a meeting with waste management associations/clusters in Beja and then with a seminar in Lisbon at the 27th European Biomass Conference & Exhibition.

Success factors for wood waste valorisation

One task of the project focused on the identification of common success factors that have contributed to the development of wood waste ecosystems in the model regions. In all the model regions it was observed that the existing legislation and policies contribute to promote the valorisation of wood waste. The following success factors can be highlighted as the ones that need to be implements in regions for sustainable wood waste use:

- The landfilling of waste wood together with household wastes is usually banned, or heavily discouraged with very high disposal fees;

- A suitable classification system is in place, which eases management of wood waste of different origins for both producers and operators;

- Presence of a good network to collect, sort and classify the wood waste;

- Presence of valorisation options for wood waste in the region; those may differ from region to region and from country to country and may include energy, recycling or both. Most of the model regions, except in Northern countries which ensure their energy independence thanks to the wastes,adopt a cascading use approach, that ranks recycling as the priority and energy after.

- Availability of solutions for the management of by-products such as the fine fraction generated by wood screening, or combustion ashes

- Presence of industrial actors in the region or country, with competences to valorise wood waste.

As an output of the task, a toolbox of EU success factors was produced and is available on the BIOREG platform.

France is tackling the issue of wood waste since few years

To have an idea of how these factors can affect the development of a wood waste value chain, one can look at the recent evolution of this sector in France. Since 2015, France has significantly improved the knowledge of wood waste, and this has helped to improve the rate of its valorisation. In many parts of Europe, where landfilling is not restricted or unincentivized, the valorisation rate of wood waste is low and can be improved significantly. By adopting a restrictive approach to landfilling, France is now seriously tackling this issue.

The first campaign to characterize wood waste in the French construction and demolition sector was conducted by the SEDDRE (building and civil engineering federation) in 2015. More than 100 phisycal-chemical analyses allowed for the characterization of the different categories of wood waste from C&D.

Between 2016 and 2018 a second major wood waste characterization campaign was conducted in Normandy and the Paris area, an initiative of several actors in France, including the Environmental Agency (ADEME), local industries (UPM, LINEX, Biofuels SAS, SUEZ) and local engineering companies (CEDEN, Biomass Normandy, CRITT Logistics), under the program ECIRBEN (Circular Economy of Wood Energy in Normandy).

About sixty physical-chemical analyses (PCI, moisture, heavy metals, PCP, PCBs, PAHs, organo-chlorines, etc.) were carried out on different categories of wood (construction, furniture, households) and a combustion test was performed at the UPM paper mill in Rouen. As in the previous study, the impact of the screening on the quality of the resulting products was studied. In addition, characterizations by type of wood waste (particle board, solid wood, OSB, MDF, etc.) have made it possible to show and to confirm differences between the different wood origins.

This program has helped to build the confidence of local industrials on the quality and quantity of the available wood waste resource. Thanks to this many industrial projects are being developed in Normandy today, with an estimated demand of several hundred thousand tons of wood waste, both for energy use and for recycling in the manufacturing of panelboards.

As an extension of this campaign, the two French eco-organizations in charge of furniture waste, namely Eco-Mobilier for households and Valdelia for industrial wood waste, have launched a new campaign to characterize wood waste from furniture. This study is being carried out under the supervision of the INERIS (National Institute for the Industrial Environment and Risks) and under the umbrella of the Ministry of the Environment. More than 300 furniture wood waste sample analyses and 2 industrial combustion tests were performed, in order to optimize the process conditions for the energy recovery this resource. In the short term, this campaign could facilitate the “end of waste status” of wood waste.

Thanks to these characterization campaigns it was possible to create a database of more than 500 wood waste analyses, including the results of the three recent French studies, in addition to results provided by ECN-TNO (Energy Research Center of the Netherlands), FCBA and other operators. Furthermore, wood waste combustion tests and lab analyses are also being carried out at the coal power plant of Cordemais in western France, aimed at specifying the conditions for the conversion of the plant by 2022.

There is still a significant unused potential of wood waste in France today, but thanks to his approach based on the extensive characterization of the resource, combined with the increase of the landfill tax in 2025 (+ 45 € compared to today), an increase in the rate of recovery is expected in the coming years and this represents a solid base for the large-scale valorization of wood waste in France and in Europe.

A circular economy approach to wood waste can bring local growth while reducing CO2 emissions

In France, by removing regulatory barriers at the national level, the wood waste industry could become a well -established sector both in the short and in the medium term. In Normandy only, around 360,000 tons of wood waste are produced annually and 40% of this amount is either exported or still unused. To date, it can be estimated that 1/3 of this resource could be likely absorbed by a local panel manufacturing company and the remaining 2/3 could be recovered for energy, displacing the use of natural gas. This would equal about 50,000 tons CO2 equivalents of emission savings by locally recovering wood waste in Normandy and a carbon storage in panels of around 20,500 tons. This could bring significant and positive socio-economic effects: it is estimated that 118 direct jobs would be created at the regional level.

The same is true for the other recipient regions of the BIOREG project. In Portugal, it is estimated that 94,000 tons of wood waste are produced annually in the regions of Alentejo and Lisbon and that the untapped or exported potential is around 57%. To date, it can be estimated that 1/3 of the resource that is collected will be oriented towards the material recovery and reuse, but only 3.5% of the available wood waste is recovered in energy. It is estimated that 2/3 of the total wood waste could be reused for energy, avoiding around 13,000 tons eqCO2 and 1/3 of the total wood waste could be reused as material, providing a stable storage of around 5,400 tons of CO2.It is estimated that 45 direct jobs could be created at the regional level by the industrial valorisation of the available wood waste.

Many other regions in Europe still have significant and untapped volumes of wood waste which could be valorised in a circular economy model. A concerted effort to fully unlock the potential of wood waste in those regions should build on a series of principles which can be resumed as follows:

A clear legislation and wood waste classification system: Landfilling of should be discouraged, good waste management principles require waste hierarchy to be followed: materials are first re-used and recycled into new products, before energy recovery and disposal. This principle should also apply to waste wood. A clear and harmonized classification and grading system of wood waste (clean, non-hazardous, hazardous, etc.) is also essential to create the right framework conditions for operators along the value chain and for trade.

Improving the quality of wood waste : In order to meet the demand of the industrial end-users both in terms of quantities and quality, it is essential to understand that different qualities of wood waste are required by the energy sector and the particle board sectors and this affects the production process or waste wood.

Efficient collection and sorting: increasing and enhancing the available local circuits and platforms to collect screen and sort of wood waste are essential steps to ensure local availability of sufficient quantities of high-quality waste wood, for stable end use markets.

In addition, it is also necessary to anticipate the tightening of health regulations regarding the handling and sorting of wood waste which generates harmful dust emissions. Appropriate equipments such as water spraying, dust extraction systems, etc. must now be available at the facilities in order to reduce dust production during those phases. Finally, to reduce the carbon footprint and GHG emissions of the value chains, it is necessary to increase the use of electrical equipments replacing diesel-powered machineries for the handling and processing of wood waste.

Find out more at bioreg.eu

Text by BIOREG Consortium

This project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement No 727958.