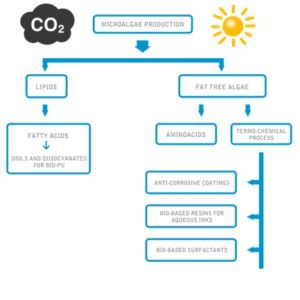

BISIGODOS project aims to address the production of valuable algae derived chemicals, amino acids and high added-value bio-resins starting from algae biomass fed directly with CO2 from industrial emissions (cement, steel factory, thermal power plants, etc.) since its cost-effective and renewable. The process is assisted by solar radiation, nutrients and sea water microalgae. The presence of main actors in the whole value chain demonstrates the critical mass of complimentary resources that will enable the project to achieve its targeted industrial, scientific and societal breakthroughs and commercial success.

The BISIGODOS consortium brings together a wealth of expertise and resources within the areas of:

- Microalgae and photo-bioreactors production and optimization

- Manufacture of amino acids for food products

- Production of conductive polymer coatings

- Bio-resin development for water-based inks

- Bio-surfactants production and bio-PU adhesives manufacturing

- End-users in the food, flexible packaging, hair care, metal industry and paints products.

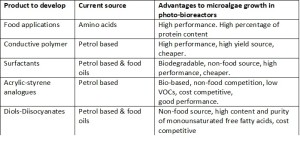

The work carried out was related to the cultivation of the alternative algae strains based on the requirements of the cases of study and optimal growth conditions, process Integration, energetic and mass balance evaluation and improvement, extraction of the lipid fraction and the transesterification of fatty acids and the production of diols and diisocyanates. Moreover, some of the compounds were separated and processed further for aminoacids, conductive polymers, surfactants and ink production. The scaling up of each selected fine chemical substance and bio-resins was studied and carried out. The regulatory, economic and environmental viability study of each selected fine chemical substance and bio-resins was carried out. Dissemination and exploitation activities were achieved along the project development as well as Project Management. The selection of each product is related with the advantages provided (Table I).

Adoption of Innovative Approaches

To develop these new technologies, the project will adopt several innovative approaches:

– The production, optimization and CO2 energetic balance improvement of new algae strains.

– Optimizing the photo-bioreactors by reducing up to 65% CO2 emissions in industrial plants to produce high value added products.

– Study and adaptation of separating algae components which are based on hybrid technologies.

-Production of algae derived chemicals for surfactant applications and amino acids for food applications. Obtaining a broad range of amino acids and protein hydrolizate products.

-Production of bio-based algae resins from fatty acids and bio-oil aromatic moietis.

Challenges faced

The approach for the strains selection in production requires two consecutive phases: screening in accordance with the specifications of the end user’s requirements and industrial screening.

The separation of components from the liquid phase is the most important challenge. The HTL step produces 60‐200 compounds from 20‐30 different chemical groups both in aqueous phase and oil phase. In the process separation, components are divided into groups based on their physical or chemical properties. This is due to the fact that components from different chemical groups can have the same physical property (like boiling point). It has to be taken into account that several parameters affect the HTL process, such as type of biomass, temperature, water content, catalyst and space time.A change in these properties results in the modification of product composition which can lead to changes in the needed separation steps.

About BISIGODOS:

The project BISIGODOS is funded by the European Commission (FP7/2007-2013) under grant agreement no. [613680].

The project BISIGODOS is funded by the European Commission (FP7/2007-2013) under grant agreement no. [613680].

The partners of BISIGODOS project are the following: AIMPLAS (coordinator), PDC, PHYCOSOURCE, GBR.AT, CASPEO, VTT, 3V TECH, BECKERS, SUNCHEM, CUSA, CRODA, BFS, BANGOR and WARWICK.

For more details, visit BISIGODOS website.

Text by Ana Palanca Roig, Investigación y Desarrollo Research & Development.