Wood stoves are commonly used for space heating in many countries, particularly those with relatively abundant resources for the production of firewood. However these stoves are often blamed for their modest combustion efficiency, their high emissions of particulate (PM) and volatile organic compounds (VOCs). This behaviour can contribute sensibly to increasing local air pollution, a serious problem especially in urban areas. In some countries, such as Italy, some regional authorities were forced to restrict the use of wood burning appliances, in order to guarantee the respect of air pollution limits, especially in winter time.

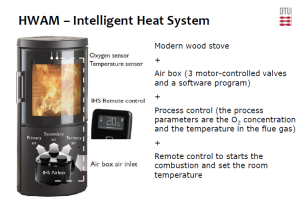

A modern digitally controlled woood stove

A collaborative project between the Technical University od Denmark Chemical Engineering and the stove manufacturing company HWAM A/S, started in 2012, has led to the development of a new type of modern automatic wood stove, which achieved a high efficiency of combustion and significantly reduced emissions. The usual bad firing habit which is common in traditional wood stoves was corrected by adopting a digital control system which ensures constant and optimal temperatures and overall oxygen concentrations in the combustion chamber. The autopilot IHS stove consists of a modern wood stove with three separate combustion air inlets, a control system composing of measuring devices for vital process parameters and a system for controlling valves to regulate the individual air flows. The air box, placed below the combustion chamber, contains three air inlet valves and the software for controlling them. The process parameters are the oxygen content, flue gas temperature and room temperature. The user can set the desired room temperature with a remote control. Laboratory tests were conducted on the stove and measurements were made to study the functionality and the combustion process.

High efficiency and low emissions

The results indicated an efficiency of 80.7%-83.4% , CO composition in the range of 1000-1250 ppm, particulate matter in the range of 1.8-2.5 grams per kg of wood charge and organic compound compostion in the range of 51-76 mg/Nm3. Overall, the experiments showed that the digital control of the combustion process ensures constant and optimal temperatures and overall oxygen concentrations in the combustion chamber. This results in low PM and CO emissions, well below current standards, and high energy efficiency. The stove was further optimized based on the experiences gained from field tests.

Emission measurements at the research wood stove set-up at DTU Chemical Engineering to study the influence of various conditions, showed an increase in the emissions of CO, VOC and PM in the ignition phase, a small particle peak in the flame phase, and an increase of CO emission in the char combustion phase, due to decreasing temperature in freeboard. With the progression of the process, almost no particle emissions were observed in the char combustion phase. Significantly reduced emissions and high efficiency were observed for the IHS stove, compared to manually controlled stoves.

This post is based on the paper by Jytte Boll Illerup et al. “Intelligent Heat Systems – High Energy Efficient Wood Stoves with Low Emissions of Gases and Particles“, presented at the 23rd European Biomass Conference and Exhibition.