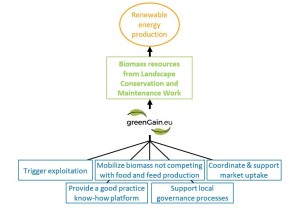

Today, Europe´s energy sector is facing rising demand, volatile prices and disruption to supply, all in the frame of great concern to reduce the environmental impact of energy production. To tackle these problems the European Commission has launched plans, which will ensure secure, affordable and climate-friendly energy for EU citizens and businesses. The aim of the Horizon 2020 financed project greenGain is to contribute to these plans by fostering the production of renewable energy from biomass deriving from landscape conservation and maintenance work (LCMW) (Figure 1).

For this reason, the eight project partners from Spain, Italy, Czech Republic and Germany regard technical, financial, legal, social and environmental aspects on the EUand regional level. A fundamental part of the greenGain project is the initiation and realisation of strategies to utilize biomass from LCMW in model regions of the four project countries. For this, the involvement of local stakeholders is vital, which was ensured by linking seven regions to the project either as associated partners, forming part of the consortium, or as external stakeholders committed with the project. In these regions, greenGain closely cooperates with local actors, who are responsible for LCMW and for the regional biomass residue management. Moreover, service providers, farmers and forest owners, their associations, NGOs, as well as energy providers and consumers contribute with their expertise to the project goals.

Producing renewable energy with a by-product

The feedstock considered in greenGain derives from work, which is carried out in public interest with the primary objective of nature conservation and landscape management, but also safety and aesthetic aspects (e.g. from roadsides, public greens, waterways). Residues from plantations and harvesting an economically viable product are not considered as LCMW feedstock, unless such plantations form a typical and protected landscape picture (e.g. olive groves in Italy). The biomass can be woody, herbaceous or a mix of both and is characterised by a spatially scattered and seasonally fluctuating supply.

In many cases, actors involved in the handling of this material encounter financial and technical constraints, uncertain responsibilities, unclear legal requirements and a general lack of information on the biomass (amount, type, etc.). Yet, with its energetic utilisation a by-product of regular and mandatory management of public areas contributes to local energy cycles and renewable energy production. Also selling this feedstock, or the thereof produced energy, is a possibility for financial compensation for maintenance costs. A number of EU regions already recognise LCMW biomass as a local renewable resource and perform activities to explore its chances and challenges.

The typical utilisation technologies are composting, anaerobic digestion and combustion. However, the conversion of the feedstock to energy or an energy carrier is exceptional and the biomass is mostly composted. In all EU countries, the legal frameworks consider the energetic utilisation of biomass resources and provide different feed-in tariffs to support these types of energy source. In most countries the management and the use of biomass from maintenance work is part of the environmental and the waste management law. In this context, the declaration of biomass from LCMW as waste is a crucial barrier for its utilisation for energy generation. In Europe, there is no policy, law or finance tool which exclusively deals with this kind of material and its use for energy production.

Integrating biomass potentials in exhisting supply chains

The utilisation of biomass from conservation and maintenance work asks for consideration of the unique landscape and vegetation and the corresponding management needs in a region of interest. In order to be able to fulfil the task presented in Figure 1, the Consortium of greenGain thus analysed the status quo of the existing LCMW types and the main biomass consumers on the example of the project regions. The biomass potentials of the different types where then assessed with expertise from local stakeholders and literature analysis.

The results provide a quantifiable base for further promotion of LCMW material utilisation and the establishment of regionally adjusted production chains. Despite fundamentally different conditions in the analysed regions, none of the cases showed strong restricting factors hindering the implementation of the maintenance work. However, the thereby produced biomass is usually dispersed and its potential per unit of territory is much lower than biomass from agrarian or forestry areas (e.g. in the Spanish pilot regions up to 16 times more straw and stalk residues and 29 times more forestry residues). Still, even if it cannot constitute as main biomass source by itself, by using specific business models, the integration of the sustainably available LCMW material in other supply chains is realistic and it can become part of integrated logistical solutions.

Avoiding CO2 emissions

Numerous thermochemical and biochemical technologies are available for the conversion of biomass into energy and fuel. The suitability of biomass as feedstock for a conversion process depends upon its composition and heatingor calorific value. Figure 2 illustrates examples of biomass potentials of selected LCMW biomass types from the greenGain model regions and cumulative EU‐27 + Switzerland (shown on secondary x-axis). Note, the availability of technology does not guarantee the efficient feasibility of the entire process chain as the economy of scale is another deciding factor in need of consideration. An exemplary estimation was conducted of the greenhouse gas (GHG) avoidance due to the use of wood chips from the management of the characteristic hedge- and tree rows on banks in the German pilot region Friesland. The calculations are based on the process applied by a regional company for landscape management works, which markets about 15,000 m³ of such wood chips per year. The fuel is predominantly sold as quality chips for small heating systems. With wood fuel being CO2 -neutral, most GHG-emissions occur during the chip production processes after diversion from the formerly applied uses composting and traditional Easter bonfire.

Numerous thermochemical and biochemical technologies are available for the conversion of biomass into energy and fuel. The suitability of biomass as feedstock for a conversion process depends upon its composition and heatingor calorific value. Figure 2 illustrates examples of biomass potentials of selected LCMW biomass types from the greenGain model regions and cumulative EU‐27 + Switzerland (shown on secondary x-axis). Note, the availability of technology does not guarantee the efficient feasibility of the entire process chain as the economy of scale is another deciding factor in need of consideration. An exemplary estimation was conducted of the greenhouse gas (GHG) avoidance due to the use of wood chips from the management of the characteristic hedge- and tree rows on banks in the German pilot region Friesland. The calculations are based on the process applied by a regional company for landscape management works, which markets about 15,000 m³ of such wood chips per year. The fuel is predominantly sold as quality chips for small heating systems. With wood fuel being CO2 -neutral, most GHG-emissions occur during the chip production processes after diversion from the formerly applied uses composting and traditional Easter bonfire.

The approach excludes emissions from felling of trees and forwarding to a collection place, but is in line with the ECdirective for accounting of fuels from residues. The production and use of the respective 3,750 t/a wood chips results in a total GHG output of about 300 t/a CO2 -equivalents. At a water content of 12.6% the lower heating value of 1 tonne wood chips is about 16 GJ, totalling to 60,000 GJ or 4,400 MWh per year. Assuming replacement of oil as fuel for central heating, this amount of wood chips substitutes 1,280 tonnes or 1.5 million litres of heating oil every year. Compared to the typical GHG-burden of 89.5 g CO2 /MJ for oil based central heating, the use of these Frisian hedgerow management wood chips saves over 94 % of GHGemissions, a total avoidance of nearly 5,000 t CO2 -equivalents.

Know and heed your local situation

In order to optimize the use of LCMW resources for energy purposes each case requires a specific assessment. When attempting to implement a new or optimised production chain for LCMW biomass the following factors need consideration:

• Local final consumers/ local demand and existing feedstock types up to 50 km distance from final consumer;

• Feedstock composition, conversion technologies, equipment availability and site conditions;

• Feedstock quality in terms of chip quality, ash and water content and potentials for improvement;

• Stakeholders of the local production chain and their lines of communication;

• Relevant administrative and management policies, possible institutional support;

• Environmental impacts through the value chain;

• Possible constraints through lack of public acceptance The market for energy utilisation of renewables to heat and power is in most countries currently not growing.

This is mainly caused by the reduction of subsidy schemes and higher technical efforts needed for clean small scale combustion and fermentation. This consequently limits the increase of the share of LCMW material in the energy mix. Further, environmental effects and the socio economic behaviour of the local population can vary tremendously between supply chains and different case studies. However, as the main reason for maintenance work is not the generation of feedstock but conservation of landscape, safety of roads or park maintenance, which all need to be performed without alternative, the energetic utilisation of the thereof produced biomass can avoid GHG-emissions and reduce costs of operation by generating additional income.

This project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement No 646443. The sole responsibility of this publication lies with the author. The European Union is not responsible for any use that may be made of the information contained therein.

This project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement No 646443. The sole responsibility of this publication lies with the author. The European Union is not responsible for any use that may be made of the information contained therein.

For further information about the project: www.greengain.eu; c.volkmann@fnr.de

This article is by Aline Clalüna, Chamber of Agriculture Lower Saxony, Germany, Dr. Christiane Volkmann, of FNR, Germany, and Dr. Simon Kühner, SYNCOM R&D Consulting, Germany.