“Manure is a waste from agriculture polluting the air and the sea. No, manure is a valuable resource which can fertilize crops and create green energy and green jobs.” Opinions on manure differ – and both of the opinions above may be right under certain conditions. However, regardless of the opinion on manure, we have a common responsibility to handle it with proper care and without harming the environment. Animal husbandry delivering meat, milk and eggs is an important part of agriculture in the Baltic Sea Region. For increased animal production, high amounts of protein feed is imported into the region. While only a part of the nutrients in the feed are converted into consumable animal products and even less are exported out of the region, a surplus of nutrients is created. This surplus is found in different wastes and by-products, the main by-product of animal production being manure.

Today, 187 million tons of manure is produced annually from cattle, pig and poultry in the Baltic Sea Region. Most of it can be found in Poland, Denmark and the northern German states with coastline to the Baltic Sea. Also the intensive livestock production in Leningrad Oblast of Russia produces high amounts of manure.

The manure challenge addressed by Baltic Manure

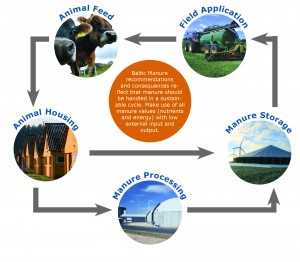

The manure management chain is initiated with animal feeding and excretion. By optimising the amount of carbon and nutrients fed to animals, less of them are also excreted into manure. This is an effective way to reduce the environmental impact of animal production, however manure is inevitably still produced and needs to be handled, therefore the project Baltic Manure focuses on the actual manure containing steps in the management chain: animal housing, manure collection, processing, storage and field application. Among these, manure processing is the latest addition into the management chain. It encompasses different technological solutions to make enhanced use of manure energy content and nutrients while simultaneously minimising emissions. Manure processing technologies may be simple, such as mechanical separation or manure cooling, or include several process steps for instance from biogas production to struvite precipitation and membrane separation.

Basically, the project Baltic Manure seeks to improve the understanding of cost-effective and environmentally sound manure management, to recommend better solutions to enhance utilisation of manure as a resource and thereby to reduce harmful outputs into air and water, and ultimately to stimulate business involvement in these good solutions. Baltic Manure is all about finding the intrinsic values in manure (carbon, nutrients) and turning these values into marketable products.

Biogas: a key manure solution

There are different types of manure, from slurry to different solid manures. The ratio of slurry and solid manure varies significantly in the Baltic Sea Region and affects the technological choices for manure management. For instance, in Denmark 80% of all manure is slurry, while in Poland 90-95% of manure is solid.

There are different types of manure, from slurry to different solid manures. The ratio of slurry and solid manure varies significantly in the Baltic Sea Region and affects the technological choices for manure management. For instance, in Denmark 80% of all manure is slurry, while in Poland 90-95% of manure is solid.

Solid manure can be processed by incineration and thermal gasification in order to retrieve its energy content, to recycle phosphorus and to reduce the amount of manure significantly. It can also be composted to preserve the nutrients and give the carbon as humus back to the soils. However, manure incineration is a controversial issue in most Baltic countries and practiced only in Sweden. Thermal gasification is at its developmental stage yet and composting does not make use of the manure energy content. All these technologies also loose all or most of the valuable nitrogen in manure. Thus, Baltic Manure does not recommend these handling technologies at present.

The most recommendable and best available manure processing technology is anaerobic digestion. Baltic Manure has shown it makes the most value out of manure. It allows simultaneously to utilise manure energy content as heat, electricity or biomethane (replacement to natural gas, transport fuel), to recycle manure nutrients along with nutrients from other organic materials, to enhance reuse of nitrogen, and to mitigate emissions to air and water.

However, biogas is not a ‘stand-alone’- technology and in every case the combination of choices in the entire manure management chain should be judged from an economic, technical and environmental point of view. Baltic Manure has made recommendations on how to improve manure utilisation in biogas plants.

Recommendations for manure based biogas

- Farm-specific business plan for investments and benefits should be made before deciding to build a biogas plant – to ensure its economical base.

- The right digestion technology should be chosen depending on the manure type to be digested – the most mature technologies are for slurry.

- Technologies for digesting solid manure should be developed or co-digestion with slurry promoted – including technologies for pre-treating to improve degradation and thus biogas production.

- Strict methane and ammonia emission mitigation is necessary after digesting manure for biogas in order not to jeopardize the environmental benefit of biogas. This could be obtained through:

- post-digestion tank and covered storage with biogas collection to ensure minimal methane emissions;

- soil injection or acidification in field application to ensure that the high ammonium nitrogen content in the digestate is directed to the crops;

- co-substrates for improving energy production of slurry digestion and to enhance overall nutrient recycling should preferably be manure-derived, such as source-separated solid manure, deep litter or mechanically separated solid fraction of slurry, or other wastes without uses as feed or food. The use co-substrates of annual energy crops, such as maize, should be carefully considered and minimized due to their environmental drawbacks.

- Biogas usage – heat, electricity and/or biomethane – should be fit into the national and regional energy strategy;

- Cost-effective small scale upgrading technology from biogas to biomethane should be developed.

Manure biogas potentials

Baltic Manure concludes that biogas is the best solution for manure energy use today. Yet it is calculated that only around 2% of all cattle, pig and poultry manure in the Baltic Sea region (excluding the German states on the shore) is presently used for biogas – with a large variation between countries. Subsequently, the unutilised potential for manure biogas is immense.

The annual theoretical energy potential of all this manure is 38-74 TWh (137-266 PJ) as biogas, but obviously not all manure can be collected and used for biogas. With the assumption that only larger farms (over 100 livestock units) have a true possibility to build biogas plants, the potential is still 17-35 TWh (61-126 PJ; Luostarinen 2013). Failing to harness this potential leaves a significant amount of renewable energy currently unutilised. Thus, the project has formulated a VISION for manure energy: 25% of all manure should be used for biogas by 2025. While the German states on the shore of the Baltic Sea may already have reached the target, quite a few obstacles can be found in most other Baltic Sea countries to fulfil this ambition. Let us illustrate this with two cases:

Finland

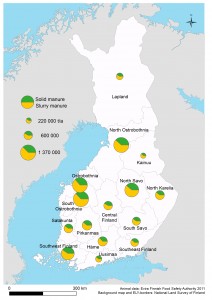

A total of 16 million tons of cattle, pig and poultry manure is produced each year in Finland. The geographical distribution of animals and thus manure was studied using the statistics on animal amounts in Finland; it was found that nearly half of the Finnish manure is solid, a manure type produced especially on smaller farms. Also, most of the cattle manure is located in the regions of North Savo and Ostrobothnia, while most of pig and poultry manure is located in the South-Western Finland.

Despite wide interest in manure-based biogas in Finland, only approximately 18.000 tons of manure is being used for anaerobic digestion in 2013. The main obstacle is profitability. The investment in a biogas plant is high and the subsidies available ineffective. Smaller farm-scale plants can get only 15-30% of investment support, while feed-in tariff for the electricity produced form biogas is totally excluded from biogas plants with less than 100 kW of efficiency. Manure is not directed into large biogas plants either, since the digestate from these plants is not legally considered manure anymore and the farmer cannot spread as much of it as raw manure, which is given a exemption for spreading volumes (kg phosphorus per ha). It is also difficult to find uses for the heat produced, especially on cattle farms, and thus part of the energy is not given a proper value.

Central Denmark Region

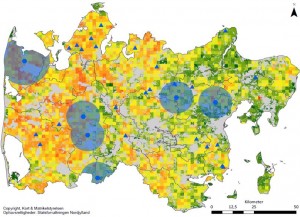

Denmark has the ambition to use 50% of manure for energy production by 2020, but a more realistic level is probably 25% by 2020 (today less than 10% is digested). The density of animal husbandry in Denmark is predominantly in the Western regions, in Northern, Western and Southern Jutland. Slurry is the predominant manure form and 22 larger cooperative biogas plans are running in 2013 with quite a few more under planning.

The Central Denmark Region covers approximately 1/3 of manure production. Large cooperative biogas plants have the advantages of economy of scale and professional management, but they also give quite a challenge for logistics and for finding suitable locations for the large industrial plants in the countryside near the biomass resources. Planning and permitting takes a long time and although the Danish parliament has agreed on higher subsidies, very few new plants have been constructed in the last ten years.

Biogas is estimated to be able to cover approximately 60 PJ (17 TWh) or 10% of total Danish energy consumption by 2030, 5.6-6.9 TWh out of which should be obtained from manure, while the rest will be produced from wastes and a modest share of energy crops. Thus it can be optimistically foreseen by the known projects that Denmark could reach 15 PJ (4.2 TWh) of biogas production, if all projects succeed – perhaps by 2020-22.

Conclusions

Biogas is part of a solution for optimal manure management in the Baltic Sea Region – providing benefits for renewable energy targets and nutrient recycling as well as emission mitigation. Many opportunities exist, along with many obstacles to remove on the way to a more sustainable manure management. The project Baltic Manure has shown that biogas can become one important way of creating new rural development and contribute to fulfil steps towards a more sustainable agriculture in the Baltic Sea Region.

This post was written by Sari Luostarinen, MTT Agrifood Research Finland and Knud Tybirk, Agro Business Park, Denmark

More about Baltic Manure

The Baltic Sea is polluted by excess nutrients, resulting in algae blooms and “dead” sea beds. A large part of the current nutrient load derives from agriculture, via emissions into air and water. The loss of nutrients to the air and into the sea is often related to intensive animal husbandry with large quantities of nutrient-rich, poorly utilized manure. The project Baltic Manure (Baltic Forum for Innovative Technologies for Sustainable Manure Management) addresses this challenge. Manure nutrients should be acknowledged as a resource and valorized by both animal and crop farmers as fertilisers. The efforts to optimize agricultural nutrient cycles for farming in the BSR by the use of the right manure handling technologies also create jobs, business, wealthy farmers and a cleaner environment. Baltic Manure is a Flagship Project in the Action Plan of the EU Strategy for the Baltic Sea Region and co-financed by Interreg Baltic Sea Region Programme. It involves 18 project partners from 8 countries with MTT Agrifood Research Finland as the lead partner. See more about the project at www.balticmanure.eu