The demand for electric power has been on the rise ever since industrialization. Decentralization of power generation is one of the approaches to solve this issue. The usage of biomass in smaller local facilities with low power generation ranges can offer clean (CO2-neutral) and environmental friendly production of heat and electricity. In the developing countries, the procedure of direct burning of biomass is still followed. Consequently, the polluting emissions cause a number of health and security issues. Small scale biogas digesters which employ the technology of fermentation of biomass are helpful in overcoming this problem. They offer advantages such as reduced green house gas emissions, enhanced sanitization, availability at lower costs and easy handling. For this reason countries such as India and China have taken enormous efforts in installing over millions of such biogas digesters in households and many of the other Asian countries have followed similar trends. By 2020, about 80 million households in China are expected to have biogas digesters serving about 300 million people. In India, 4.25 million household biogas digesters had been installed at 2011, as part of India’s efforts in implementing one of the world’s largest renewable energy programs, with different scales of technologies.

Using small-scale household digesters in European conditions

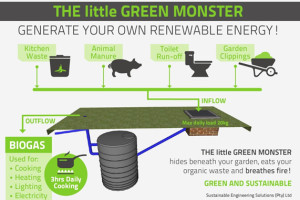

Researchers at the Institute of Combustion Technology, German Aerospace Center, explored the possibility of adopting some types of low cost household digesters, in the conditions of central European countries and the results appeared promising. The anaerobic digestion of garden wastes was investigated, as a method to obtain usable energy in form of biogas which may serve for cooking, heating, and electricity. In addition, for European countries, the coupling of biogas reactors with fuel flexible micro gas turbines may promise a highly efficient solution for the use of biomass. Results confirmed that considering the theoretical biogas yields resulting from the digestion of grass gathered from German allotments in Germany, this strategy seems possible. Among the technologies considered, the “Little green monster” digestor provided the best performance, with a production rate of 1 m3 /m3 d1 and yield of 0.7 m3/kg of substrate. Also the ACME biogas plant had sufficiently large biogas production rates. Hence, these fermenters were found to be suitable for laboratory examination under German conditions. The feasibility of these technology in providing energy for cooking and electricity with grass from German allotments as the main substrate was assessed. Batch tests with grass cuts indicated a maximum biogas yield of around 0.37 m³ per square meter of garden allotment and an approximate quality of biogas containing 55% methane and 45% CO2.

This gas could be effectively used for cooking and heating purposes. Although the amount of biogas produced would not be enough to produce electricity, the biogas obtained was considered as safe and reliable for use in a gas burner or in a micro gas turbine, and no influence was observed from potentially undesired components such as ammonia.

This post is based on the paper “Technical Evaluation of Decentralized Household Biogas Digesters”, written by Villacreses, D. Matern, A., Braun-Unkhoff, M., Riedel, U.and presented at the 23rd European Biomass Conference Exhibition.