Is it possible to reduce the impact of climate gas emissions from the transport sector through the use of wood materials? In Norway, they are trying to do so through a research centre started in January 2017 within the frame of environmental friendly energy centres (FME – Forskningssenter for miljøvennlig energi) financed by the The Research Council of Norway, private industry and regional public partners, whose name is Bio4Fuels. Its aim? To produce sustainable and economic biofuels from forests’ low-grade fractions of wood and waste from agriculture.

Is it possible to reduce the impact of climate gas emissions from the transport sector through the use of wood materials? In Norway, they are trying to do so through a research centre started in January 2017 within the frame of environmental friendly energy centres (FME – Forskningssenter for miljøvennlig energi) financed by the The Research Council of Norway, private industry and regional public partners, whose name is Bio4Fuels. Its aim? To produce sustainable and economic biofuels from forests’ low-grade fractions of wood and waste from agriculture.

The concept of Bio4Fuels

The main objectives of the centre is to develop innovative technology and support industries to realize economic and sustainable conversion of biomass to transportation fuels along with added value chemicals, particularly from lignocellulosic biomass and organic residues. To achieve the goal of sustainable production of biofuels and bioenergy, a variety of technologies will be explored, including carbohydrate processing and thermochemical approaches.

In the Hydrothermal Liquefaction (HTL) value chain, the project’s aim is to increase feedstock flexibility, reduce costs and climate impact associated with HTL as well as eliminate processing issues.

Choosing a truly integrated approach, Bio4Fuels will develop and access a variety of technical building blocks that can be combined or integrated according to industry needs, value-chain assessments and regional industrial frameworks. For highlights and more information on the achievements so far, please read the annual report.

From wood to biofuels – The main objectives of the Norwegian centre

The main goal of the centre is to provide knowledge for the production of biofuels as well as other valuable chemical products from wood. Woody biomass, the main bio-resource in Norway and the nordic countries, is indeed used as raw material. The general aim is to contribute to reduce the climate gas emissions and to solving the central challenges within the energy sector. For this reason, the centre intends to strengthen the research environments and build networks, improve promising process technologies and develop at least four new process technologies to the pilot stage. With these objectives, the centre will cooperate with the industry about production technology commercializing, to find the best value chains measured in climate benefits and profit. Bio4Fuels also aims to provide increased Innovation, value creation and profile energy research and will contribute to a knowledge-based debate. Finally, the centre will work also to increase the biofuels production efficiency with 20% and reduce the biofuels production costs with 30%.

Tha annual report and beyond – past and future main achievements

Bio4Fuels has established its international links and associated projects with research partners and stakeholders participating in an additional 4 new EU projects. We have also taken up a role in the in the Sustainable Biofuels Innovation Challenge – Mission Innovation as well as in the IEA Bioenergy Task 39 and 45. The centre has organised several workshops and webinars and contributed greatly to education of PhD and master students in Norway.

Main scientific highlights and results from the annual report are listed below.

Biofuels and climate change; Forest for sustainable flying, a paper published in Nature Sustainability: Renewable jet fuels promotes sizeable climate mitigation benefits. Sometimes, though, this comes at a cost of unexpected implications to other Sustainable Development Goals. Yet, most of these adverse side effects are attenuated when improved conversion technologies and cleaner inputs are used for renewable jet fuel production.

Liquid biofuels; HTL: Inorganics (ash) present in the biomass may cause operational challenges, e.g. corrosion and reactor clogging. It is therefore important to be able to predict and understand their fate (speciation and phase distribution) with the aim of mitigating any detrimental effect, especially when upscaling the process. Predictions for temperature dependence in HTL were obtained for several inorganic compounds.

Biofuels end use; In-flame combustion processes: diagnostic development of diffuse back-illuminated extinction imaging of soot in engine tests. The method provides high temporal and spatial resolution of the line-of-sight optical density of soot (KL) in compression ignited fuel sprays relevant to automotive applications.

Biofuels resources; Novel enzymatic saccharification mechanism: In collaboration with industry partners, the Bio4Fuels research team has successfully applied a novel enzymatic mechanism for biomass saccharification. In 2017, a researcher from INRA (Fr) and the NMBU team discovered that oxidative enzymes called LPMOs (lytic polysaccharide monooxygenases) do not need oxygen but hydrogen peroxide to break down cellulose. Since then the Bio4Fuels team and industry partners have been working on developing an industrial setup in order to harness LPMO action in a more efficient way.

Discover more about Bio4Fuels at the upcoming HTL workshop

The Bio4Fuels centre will participate in the Expert Workshop: Potential of Hydrothermal Liquefaction (HTL) routes for biofuel production on November 19th, 2019 in Brussels with the aim of highlighting the state of art and challenges for this promising conversion technology. The partners will illustrate the status of the current activities and the prospects for industrial uptake of the processes. Signup for the workshop and join us in Brussels.

The Bio4Fuels’ Consortium

The Bio4Fuels centre brings together leading Norwegian research institutions and universities, key national and international industry partners, major forestry resources owners and regional authorities into one common initiative on research, innovation and education in the production of energy carriers from renewable resources.

The Bio4Fuels centre has an annual budget of approximately 3.4 M Euro.

The Bio4Fuels Management is composed by

- Host and administration: The Norwegian University of Life Sciences, NMBU

- centre leader: SINTEF.

FME – what is it?

Bio4Fuels is a research centre for environmental friendly energy (FME – Forskningssenter for miljøvennlig energi). The establishment of these types of research centres is a consequence of a settlement reached by the Norwegian parliament in 2008 (Klimaforliket).

The FMEs represent a long-term commitment in renewable energy, energy saving, CO2 handling and social sciences. The cooperation between researchers, industry and public management is essential in developing competence at an international level in the FMEs.

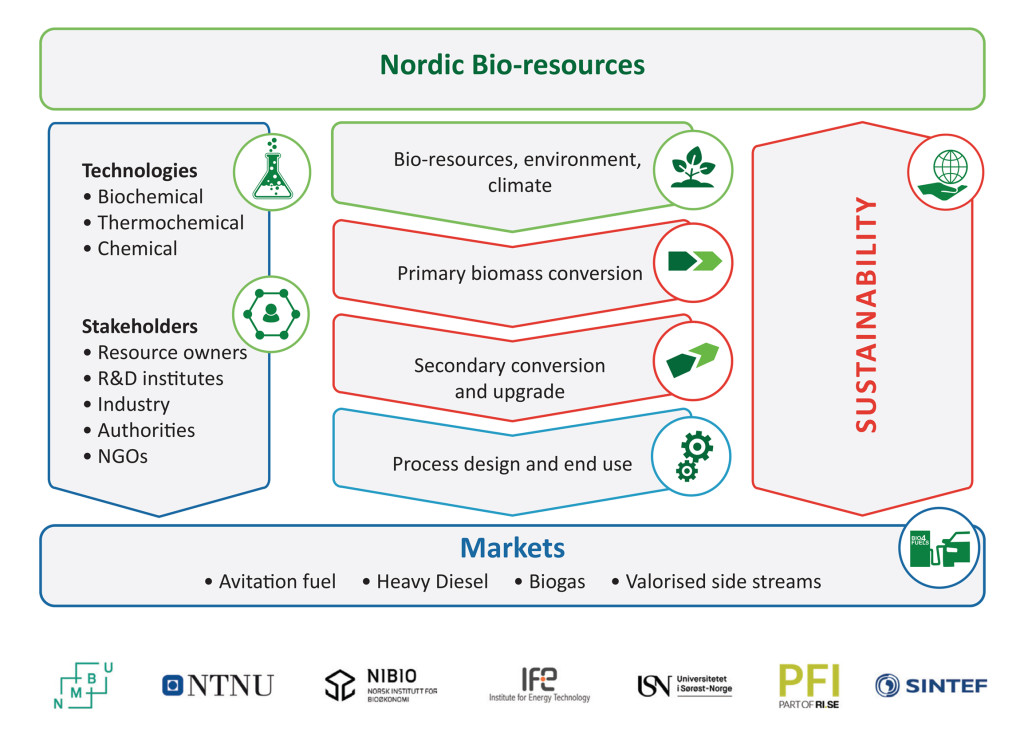

The Bio4Fuels centre consists of sub-projects of most of them representing value chains. In addition, there are cross disciplinary sub-projects associated with the value chains such as feedstock availability and sustainability, product quality and techno economics. The centre concept is shown in the figure below:

The following figure shows industrial and public stakeholders in Bio4Fuels centre

The Research partners are: NMBU – The Norwegian University of Life Sciences, SINTEF, NTNU – The Norwegian University for Science and Technology, NIBIO – The Norwegian Institute of Bioeconomy,, IFE – Institute for Energy Technology, RI.SE PFI – Research Institutes of Sweden – Paper and Fiber Institute, USN – The University of South East Norway.

For the Industry Partners see figure above or consult the updates which can be found in the annual report.

Text by Judit Sandquist, leader of the Liquefaction value chain in Bio4Fuels