Most micro combined heat and power (CHP) systems sold on the market today use fossil fuels such as natural gas and heating oil, which – although more efficient and environmentally friendly than separate heat and power production – still lead to greenhouse gas (GHG) emissions. While there are some micro CHP systems on the market which use renewable biomass, these typically suffer from lower efficiencies and, due to particular challenges associated with biomass combustion (e.g. impurities or high moisture content), they must be used with high quality biomass fuels which can be costly.

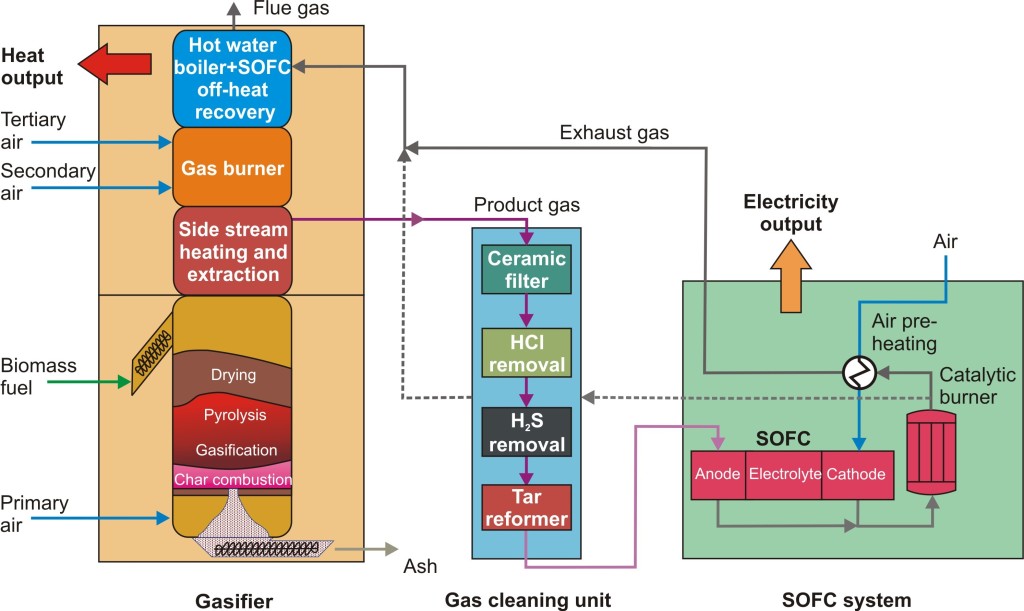

To overcome these challenges, a new innovative, highly efficient and fuel flexible micro-scale biomass CHP technology has been developed within the EU Horizon 2020 project “FlexiFuel-SOFC“ (GA No. 641229, 2015-2019) for the capacity range of 25 to 150 kW (fuel power). By integrating a small-scale fixed-bed updraft gasifier, a compact gas cleaning system and a solid oxide fuel cell (SOFC), the technology has been developed to be cost efficient, robust and capable of using a wide fuel spectrum (e.g. wood pellets/chips of various sizes and moisture contents, short rotation coppice, selected agricultural fuels). It does this while still achieving high electric (more than 40% related to the heating value of the gas entering the SOFC system) and overall efficiencies (up to 90 %), as well as incomparably low gaseous and nearly zero particulate matter emissions – something almost unheard of in small-scale biomass systems.

FlexiFuel-SOFC project

Running since 2015, the FlexiFuel-SOFC project will conclude in 2019. During the project, a comprehensive methodology was applied which incorporated the detailed engineering technology development, as well as a wider assessment of the potential market, environmental, and technical performance of the technology. The final results and achievements of the project were recently presented during a half-day project seminar at the European Biomass Conference (EUBCE) 2019 in Lisbon, Portugal. In the course of the first part of the FlexiFuel-SOFC project seminar, relevant stakeholders and other participants were informed about the technical achievements of the exciting new technology. This included detailed explanations of the development for each key component: the gasification system, the gas cleaning unit, and the SOFC stacks for efficient power generation. The technology development was based on process simulations, computer aided design of the single units and the overall system, risk and safety analyses, test plant constructions and the performance and evaluation of test runs (using different biomass fuels). Complementary to the technical development and the performance of test runs, technology assessments in the form of risk assessments, techno-economic evaluations, environmental and overall impact assessments as well as comprehensive market studies regarding the potentials for application of the new technology took place, in order to ensure that the engineering design would lead to a final product that was both economically and environmentally attractive on the market.

At the end of the project, the consortium was able to prove that the FlexiFuel-SOFC system represents a technological milestone for small-scale biomass combustion by achieving a Technology Readiness Level of TRL 5, and significantly outperforming present state-of-the-art micro CHP technologies. During pilot testing, the FlexiFuel-SOFC technology was able to achieve fuel-flexible production of low-carbon renewable heat and power with almost zero emissions of carbon monoxide (CO), organic gaseous compounds (OGC), hydrogen chloride (HCl), sulphur oxides (SOX), polycyclic aromatic hydrocarbons (PAH), and particulate matter (PM), while also achieving very low emissions of nitrogen oxides (NOX), an electric efficiency of 40 % (for the SOFC), and an overall efficiency approaching 90 %. This milestone was reached thanks to the use of the gasification approach which produces a product gas with ultra-low particulate matter and condensed alkaline compound concentrations, in combination with an integrated gas cleaning system for PM and HCl removal, desulphurisation and tar cracking, as well as an optimized SOFC system which can tolerate a certain amount of tars and even use them as a fuel.

FlexiFuel market potential

Based on techno-economic analyses of the technology, the FlexiFuel-SOFC would be most economically attractive for consumers with high electricity and heat requirements, which would allow the unit to run more frequently. In countries with favourable feed-in tariffs, feeding the electricity into the grid is the most economically attractive option though in some countries (e.g. Germany), self-consumption may be more attractive. Naturally, this depends on the regulatory framework and financial incentives in the country where it would be installed. This was a key finding of the detailed market study, which analysed the strengths, weaknesses, opportunities and threats for the FlexiFuel-SOFC system in several target countries, as well as the potential availability and costs of various biomass fuels across Europe. As part of a long-term technology roadmap, the consortium estimates the market potential for FlexiFuel-SOFC systems in the EU in the region of 2,000 units per year by 2030, with up to 60,000 systems installed by 2050. The main factors influencing the market potential are the number of full load hours required for economic operation, the final cost of the product when brought to market, and costs of competing other technologies.

Based on techno-economic analyses of the technology, the FlexiFuel-SOFC would be most economically attractive for consumers with high electricity and heat requirements, which would allow the unit to run more frequently. In countries with favourable feed-in tariffs, feeding the electricity into the grid is the most economically attractive option though in some countries (e.g. Germany), self-consumption may be more attractive. Naturally, this depends on the regulatory framework and financial incentives in the country where it would be installed. This was a key finding of the detailed market study, which analysed the strengths, weaknesses, opportunities and threats for the FlexiFuel-SOFC system in several target countries, as well as the potential availability and costs of various biomass fuels across Europe. As part of a long-term technology roadmap, the consortium estimates the market potential for FlexiFuel-SOFC systems in the EU in the region of 2,000 units per year by 2030, with up to 60,000 systems installed by 2050. The main factors influencing the market potential are the number of full load hours required for economic operation, the final cost of the product when brought to market, and costs of competing other technologies.

In addition to the techno-economic and market analyses, an Environmental Impact Assessment was also performed to illustrate what impact an EU-wide rollout of the new technology could have on key environmental indicators including total emissions of TSP, CO, OGC, NOX and GHG. As net emissions from the FlexiFuel-SOFC CHP system include contributions from both fuel combustion as well as avoided emissions from the electricity grid, which is more emission intensive than the FlexiFuel-SOFC system, the total emissions for certain pollutants may even become negative.

While further development work is still needed to perfect the technology and bring it to the market, the FlexiFuel-SOFC system has the potential to revolutionise the use of biomass in micro CHP applications in Europe whilst at the same time improving local air quality, reducing GHG emissions, enhancing member state energy security by utilising abundant residual biomass fuels, and stimulating regional economies.

![]() This project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement No 641229

This project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement No 641229

Project website for further information: www.flexifuelsofc.eu

FlexiFuel-SOFC system illustration

Text by

Ingwald Obernberger1, email: obernberger@bios-bioenergy.at

Thomas Brunner1, email: brunner@bios-bienergy.at

Michael Kerschbaum2, email: michael.kerschbaum@windhager.com

Thomas Götz3, email: thomas.goetz@wupperinst.org

P.V. Aravind4, email: p.v.aravind@tudelft.nl

Robert Makkus5, email: robert.makkus@hygear.com

Stefan Megel6, email: stefan.megel@ikts.fraunhofer.de

Martin Hauth7, email: martin.hauth@avl.com

William Zappa8, email: w.g.zappa@uu.nl

1) BIOS BIOENERGIESYSTEME GmbH, Hedwig-Katschinka-Straße 4, A-8020 Graz, Austria

2) Windhager Zentralheizung Technik GmbH, Seekirchen, Austria

3) Wuppertal Institut für Klima, Umwelt, Energie gGmbH, Wuppertal, Germany

4) Delft University of Technology, Delft, the Netherlands

5) HyGear BV, Arnhem, the Netherlands

6) Fraunhofer Institut für Keramische Technologien und Systeme, Dresden, Germany

7) AVL LIST GmbH, Graz, Austria

8) Utrecht University, Utrecht, the Netherlands