There are many technologies for the conversion of cellulosic biomass and other residues which are under development and research: this scientific know-how is not yet widely known but it would be more than worthy of attention.

Transport biofuels offer the opportunity to reduce GHG emissions in the transport sector, to diversify the sources of energy carriers, to reduce the energy import bill and to support regional development. They can be produced from a multitude of biomass feedstocks, by applying various conversion routes and by substituting either gasoline, diesel or natural gas. Well-established biofuels include biodiesel (FAME), sugar or starch-based ethanol and hydrotreated vegetable oil (HVO).

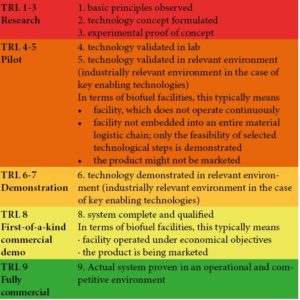

However, these “conventional” biofuels are based on biomass that could alternatively be used for food or feed production, and due to sustainability considerations public support has shifted towards “advanced” biofuels being produced from non-food/feed biomass. Technologies for the conversion of lignocellulosic biomass (such as forestry and agricultural residues) and other wastes and residues are not yet technologically mature and cost competitive. A large number of different technologies are under research and development at different Technology Readiness Levels. While those at TRL 7-9 are well-known, other technologies at lower TRL levels would deserve more attention.

Synthetic liquid fuels from biomass via gasification

Various technologies are based on the gasification of lignocellulosic feedstock and further conversion of the synthesis gas to useful products. While the production of biomethane has already been demonstrated at semi-industrial scale (GoBiGas project), the production of FT-liquids is currently being demonstrated at a production rate of 1 barrel per day, and mixed alcohols are at pilot scale. Another technology, combining gasification, Fischer Tropsch synthesis and aqueous phase reforming is under investigation by the project Heat-to-Fuel. Adapting the gasification process conditions to produce a tar free gaseous intermediate is of high importance for the subsequent liquid fuel synthesis and is being investigated within the project BECOOL. The microbial fermentation of syngas for the production of alcohol is part of the scope of the project AMBITION.

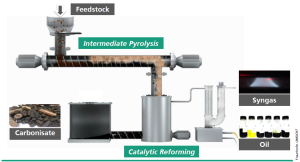

Pyrolysis technologies

The production of pyrolysis oil has been known for quite a while, but stabilizing the oil and further processing it into diesel substitute is still a challenge. Current research includes investigations of further processing pyrolysis oil within fossil oil refineries and co-firing it in coal-fired CHPs. One example of a research project that combines pyrolysis, catalytic reforming and hydrodeoxygenation in one facility is the project To-Syn-Fuel.

Hydrocarbons from cellulosic sugars

Sugars obtained from the processing of lignocellulosic biomass can be converted to a range of different hydrocarbons which are suitable for blending with diesel and gasoline or even for a further processing into bio-kerosene. The sugars can either be processed via microbial fermentation using engineered yeasts (Amyris firstof- its-kind commercial plant in Brazil producing farnesene), or through aqueous phase reforming APR (Virent demonstration plant producing renewable diesel). Both pathways provide chemical intermediates that can be processed into a wide range of chemicals and fuels.

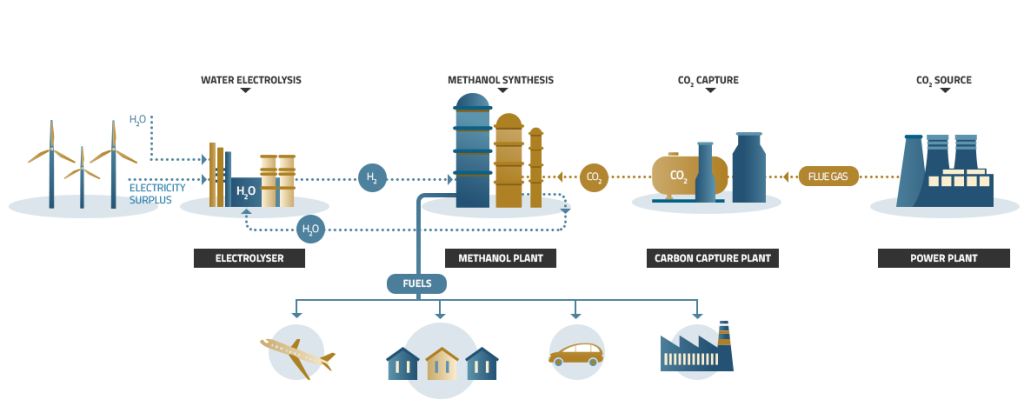

Power-to-fuel technologies

More recently, interest has risen in the utilization of excess renewable electricity to produce hydrogen via electrolysis and in the subsequent further processing into liquid or gaseous transport fuels. Technologies that combine this renewable hydrogen with a carbon source include synthesis of methanol from captured carbon dioxide using surplus electricity such as project MefCO2, and the e-crude production pathways of Sunfire.

biofuels and intermediate bioenergy carriers production: filters allow to search through

data that have been collected in a collaborative effort of ETIP Bioenergy Steering Committee

and Working Groups, several IEA Bioenergy Tasks (Task n. 33 and 34), companies and experts.

ETIP BIOENERGY workshop on low TRL biofuel technologies

The low TRL technologies described above cover only a minor part of the ongoing research. The sector is wide, and a vast number of R&D projects aim to further develop new biofuel production technologies. Both public funding and support and private financing will be required to reduce costs and to improve performance of renewable fuels regarding efficiency, the environment and society. An overview of European pilot and demo facilities is available online at the ETIP Bioenergy website (http://etipbioenergy.eu/databases/production-facilities). ETIP Bioenergy will present several low TRL biofuel technologies during a workshop taking place on 4th June in Brussels, combined with offering opportunities for B2B (Business to Business) matchmaking.

Find out more about the event here.

Some HORIZON 2020 Projects focuse on increasing the TRL of emerging technologies

AMBITION – Advanced biofuel production with energy system integration – is a transnational and integrated research which aims at developing a system flexibility by targeting specific aspects of the integration challenge, to create a bridge between two forms of energy carriers, e.g. biofuels and grid electricity. Project duration: 01/12/2016 – 30/11/2019.

BABET-REAL5 aims at developing an alternative solution for the production of second generation ethanol on a smaller industrial scale than the one of current ethanol plants. This kind of alternative solution will be suitable for many countries, rural areas and a large amount of feedstocks. Project duration: 01/02/2016 – 31/01/2020.

BECOOL – Brazil-EU Cooperation for Development of Advanced Lignocellulosic Biofuels – aims at fostering the cooperation between EU and Brazil in the development of advanced biofuels, from sustainable agricultural value chains, based on lignocellulosic biomass. Project duration: 01/06/2017 – 31/05/2021.

ButaNext – Next Generation Bio-butanol – mission is to develop innovative techniques to optimise biobutanol production from wheat straw, Miscanthus and municipal solid waste. The project aims at overcoming the technical and economic constraints to the use of biobutanol as an advanced biofuel. Project duration: 01/05/2015 – 30/04/2018.

Heat-to-Fuel – Biorefinery combining HTL and FT to convert wet and solid organic, industrial wastes into 2nd generation biofuels with highest efficiency. Heat-to-Fuel is bringing the next generation of biofuel production technologies towards the de-carbonisation of the transportation sector. By combining an APR with a FT reactor it plans to achieve competitive prices and a higher quality level for biofuels, as well as for life-cycle GHG reductions, with consequent savings in increased energy production. Project duration: 01/09/2017 – 31/08/2021.

MacroFuels – Developing the next generation Macro-Algae based biofuels for transportation MacroFuels aims to produce advanced biofuels from seaweed or macro-algae. Targeted biofuels are ethanol, butanol, furanics and biogas destined to heavy transport vehicles. Project duration: 01/01/2016 – 31/12/2019.

4refinery – Scenarios for integration of bio-liquids in existing REFINERY processes. The project will develop and demonstrate the production of biofuels from efficient liquefaction mechanisms integrated with upgraded downstream (hydro) refining processes in order to achieve overall carbon yields of >45%. Project duration: 01/05/2017 – 30/04/2021.

To-Syn-Fuel – the Demonstration of Waste Biomass to Synthetic Fuels and Green Hydrogen. The aim of To-SYN-Fuel is to build, operate and demonstrate the production of Synthetic Fuels and Green Hydrogen from organic waste biomass, mainly sewage sludge. The renewable liquid fuels comply with European standards for gasoline and diesel. Project duration: 01/05/2017 – 30/04/2021.

This article is by Dina Bacovsky and Andrea Sonnleitner, from Bioenergy 2020+.

Technology Readiness Level (TRL)

and Advanced Liquid Biofuels from Biomass) IEA Bioenergy demoplant website (http://demoplants.

bioenergy2020.eu/explanations.html).

As a concept originally developed by NASA in 1974, it is currently utilized by NASA, United States Department of Defence, European Space Agency and European Commission (e.g. Horizon Working Programme 2018-2020). It stands for a systematic measurement system to assess the maturity of a technology and to guarantee the comparison between different types of technologies. Such method is set on a scale from 1 to 9 (1 being the lowest readiness level, while 9 being the highest one), pointing out whether a technology is still at an early-stage kind of development or it is ready to be commercialised.