Microalgae are measured in micron. They are tiny, about 10 times smaller than a single human hair. However, the need for a microscope becomes superfluous when it comes to visualizing these organisms’ potential for biofuel production. With high oil and biomass yields, algae can produce considerably greater amounts of biomass and lipids per hectare than terrestrial biomass, having also the advantages of not competing with precious fertile agricultural land and being an efficient mean to capture CO2. Yet, large scale sustainable production of biofuels from algae is still a challenge, as it would require the use of too much water, energy and fertilizers.

Microalgae are measured in micron. They are tiny, about 10 times smaller than a single human hair. However, the need for a microscope becomes superfluous when it comes to visualizing these organisms’ potential for biofuel production. With high oil and biomass yields, algae can produce considerably greater amounts of biomass and lipids per hectare than terrestrial biomass, having also the advantages of not competing with precious fertile agricultural land and being an efficient mean to capture CO2. Yet, large scale sustainable production of biofuels from algae is still a challenge, as it would require the use of too much water, energy and fertilizers.

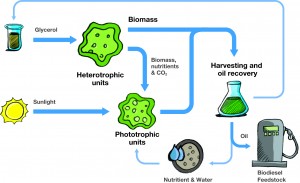

Aiming to mitigate this issue, the Integrated Sustainable Algae (InteSusAl) project was launched on 1 May 2011. The consortium intends to demonstrate an integrated approach to generate biofuels from algae in a sustainable manner on an industrial scale. The innovative method will combine two different algae growth conditions, heterotrophic and phototrophic in order to obtain high and sustainable biomass production.

The process will provide information on sustainability of phototrophic and heterotrophic algae systems at industrial scale as well as an integrated system to maximum productivity while minimizing energy and water requirements. The longer term aim is to build a 10 hectare operation to produce 1000 tonnes of biomass per year in a sustainable manner.

“There is a great potential for this combined approach with further development to effectively reduce the Europe’s GHG emissions for transport”, says the Project Coordinator, Dr Neil Hindle, from the Centre for Process Innovation (CPI, UK).

Phototrophic growth uses CO2 and sunlight to grow biomass. In this condition, the algae can use carbon dioxide from the atmosphere in raceways or buddle through photo bio-reactors (PBRs). Cell density is limited by the light penetration. Heterotrophic growth, on the other hand, does not require light, using oxygen and an organic carbon source to grow.

The project is combining the advantages of these two approaches to make a sustainable system, using the waste from the phototrophic approach to grow also heterotrophic algae and, therefore, overcoming the phototrophic growth barrier of self-shadowing of cells. However, heterotrophic growth of algae requires feeding a carbon source to the algae in a fermentation system, what raises a relevant issue for the system, since the heterotrophic units’ requirement for a carbon source results in the production of carbon dioxide.

Therefore, in order to reduce the carbon footprint, the consortium chose a waste carbon source, glycerol by-product from bio-diesel trans-esterification, to give a growth profile similar to glucose. The resulting carbon dioxide is then carbon captured into a photo bio-reactor to provide enhanced biomass cultivation.

Strain selection a key element for success

Moreover, another key step in the InteSusAl method is the strain selection, due to the imperative requirement for strong microalgae that grow considerably fast in intermittent temperature environments since, in order to be successful and sustainable.

“We often say that we know at best 1% of the microalgae. It is probably even less. It is therefore not difficult to imagine that among those 99% of unknown strains and species are very likely many that are better suited for the purpose of mass cultivation and for the extraction of biofuels. We need strains that grow well in mass cultures and are not easily contaminated, prone to viral attacks or just are unstable or die quickly. Also, since most of the space for mass cultivation is in the (sub) tropics, we need strains that resist high temperatures and tolerate large fluctuations in temperature, growing in seawater since the supply of freshwater is very limited and will represent another challenge in the near future”, highlights Lucas Stal, project partner and Senior Researcher at the Royal Netherlands Institute for Sea Research (Nioz).

InteSusAl has already obtained interesting new data and have discovered new strains with exceptional properties, which will soon be published in scientific papers. The consortium will then continue to search for new strains by attempting to isolate microalgae from various environments. Next steps would be the research on the conditions that lead to an increased lipid (fat) content of the algae by changing the growth conditions.

Lipid is the raw material from which the biodiesel is produced. The project will also look at the addition of organic compounds for increasing the algal biomass and lipid content of the cells. Suitable strains will then be transformed to cells that are tolerant to higher temperatures and suitable freshwater strains will be transformed for growth in seawater. Finally, the consortium will design mixed species cultures, believing that cultures with several species may be more stable and have higher productivities than monocultures.

Usually, cultivated microalgae have high water content and harvesting and processing requires its removal or reduction. For instance, Spirulina has a long spiral shape lending it to be harvested by microfiltration. However, harvesting microalgae is a high energy consuming process, which can make up to 30% of the total process costs. Therefore, to reduce the energy input alternative methods are needed. Here, InteSusAl is adding flocculating agents to the microalgae, chemicals that produce the flocculation process by causing suspended particles in liquids to aggregate, forming a floc. When added to the microalgae, it clusters the cells that will settle down, demanding, as a consequence, less energy for harvesting.

“At the moment we have tested if different agents are able to flocculate the microalgae strains we are using in this project. Finally the flocculants will be tested on large scale. We will also have a closer look if the medium can be re-used for growing the microalgae in order to decrease the amount of water needed. The results will definitely give answers on how you can grow microalgae on large scale and how you can improve the sustainability”, explains Ben van den Broek, project partner and Senior Researcher at WUR Food & Biobased Research (NL).

Furthermore, the project has now carried out screening of algae strains for optimal growth and oil production within the different production technologies. CPI is designing a novel low cost fermentation system that aims to allow an economic production of algae from bio-diesel glycerol. From laboratory trials each 1kg of glycerol used will produce 0.8kg of biomass. This biomass can, after extraction, obtain triglycerides for bio-diesel production and the remaining cellular material used as feed to bio-ethanol fermentation. The majority of the biomass is made via the heterotrophic module reducing the water usage by an order of magnitude. Use is made of the other nutrients that are present in the bio-diesel glycerol.

InteSusAl is co-funded by the European Commission (EC) under the 7th Framework Programme as an outcome of EU’s ambitious renewable energy targets. The EC is also participating in the funding of other two large-scale industry-led projects aimed at demonstrating the production of algal biofuels along the whole value chain, covering strain selection to algae cultivation and production, oil extraction, biofuel production and biofuel testing in transportation applications. The projects are BIOFat and All-Gas, both sharing with InteSusAl the structure of the demonstration FP7 project Algae Cluster.

Ensuring the sustainability of the process

Within the European Union, the sustainability of biofuels is considered essential. Both the Renewable Energy Directive (2009/28/EC, RED) and the Fuel Quality Directive (2009/30/EC, FQD) set legislative sustainability criteria for biofuels. Therefore, InteSusAl is considering sustainability across the whole process, in terms of both economic and environmental (closed carbon loop), implications including optimum use of algal biomass resources to enable commercialisation. In addition, during all activities, the project will use accepted Life Cycle Analysis (LCA) methodology and tools to establish the economic feasibility and environmental sustainability of the algae to biofuels demonstrator. The goal is to ensure that this project, and its subsequent wider exploitation, will create no land-for-food versus land-for-fuel issues as well as to provide relevant sustainability information to inform project direction and decision making and to allow comparison with other algae production sites. So far, the LCA has involved working with BIOFat and All-Gas to ensure there is a common goal and scope. This enables the InteSusAl to compare sustainability results, and understand how each project can improve using the lessons of others.

According to Tom Bradley, responsible for the LCA, the models for the production of equipment are currently being created, along with the draft operational model. This will show the largest energy users within the process. The project is still in the data collection stage (LCI) and the real impact will come as InteSusAl is compared to other processes.

“The data collection needs to be completed, allowing for detailed accurate models to be created. Additionally, we intend to compare with first generation biofuels. InteSusAl will hopefully result in a high efficiency, high yield methodology for creating algae biofuels. The LCA will feed into high efficiency yield methodology for creating algae biofuels to ensure that there is as low a greenhouse gas impact as possible. I believe the InteSusAl project will make a major impact on transport emissions in the EU within ten years, says Bradley, project partner from the National Renewable Energy Centre (Narec, UK).

To demonstrate the project’s integrated and sustainable approach, the consortium will operate a production unit on a 1 hectare site, growing 90-120 tonnes of dry algae per year. The current activities also include the commissioning of an industrial scale low cost fermentation unit for location on the production site.

The unit will be located at the premises of the project partner Necton, inside a national park in the Algarve region, in southern Portugal. Building work has just started with the widening of the drainage channels. The partners expect the site to be fully operative in a few months.

Moreover, InteSusAl has recently been selected for a presentation during the 21st European Biomass Conference and Exhibition, which will take place on 3-7 June in Copenhagen, Denmark. The presentation will be performed by the project coordinator, Dr Hindle, who will describe the project approach and cover the results achieved so far. EUREC Agency, the project partner in charge of dissemination, will have a booth in the exhibition area, remaining available during the whole event for further discussions.

The consortium

The InteSusAl consortium consists of six partners coming from four European countries, whose complementary expertise will enable successful delivery of the projects. The Royal Netherlands Institute for Sea Research (NIOZ, NL) provides expertise in algae strain selection and growth. The Wageningen UR Food and Biobase Research (DLO-FBR, NL), is developing harvesting techniques to minimise energy usage and additives such that the majority of the water can be recycled. The demonstration unit will be hosted in Portugal by Necton, alongside with their existing commercial photo bio-reactors. The National Renewable Energy Centre (Narec, UK) is carrying out the LCA to compare the sustainability of this approach to the other Algae cluster projects as well as to fossil fuels. Dissemination and exploitation of results are being led by the European Renewable Energy Research Centres Agency (EUREC, BE).

All partners expect InteSusAl results to be able to significantly contribute to increase the security of energy supply for European Transport needs and greater penetration of Renewable Energy Resources (RES), reducing therefore, EU’s GHG emissions. The studied algae strains may be micro, but holds a potential extremely easy to be spotted with the naked eye.

Written by Vinicius Valente – Communication Officer EUREC Agency valente@eurec.be