Emerging new biofuels obtained from sustainable biomass either from biochemical-based pathways or thermochemical-based pathways are at advanced stage of development and new investments in Europe will be boosted by the new legislative EU framework for the next 10 years.

Challenges connected to biomass logistics, trade and end-use can be overcome by upgrading to standardized and more energy-dense bioenergy carriers. Technologies like pelletization, torrefaction (solid products) and pyrolysis (bio-oils) can play a significant role in this respect. Such energy carriers can facilitate the conversion of fossil plants to biomass on large scale, thereby also contributing to the grid stability in view of the increase of variable RE power production. This increase in the availability of RE power also opens up for hybrid plants using RES power to produce hydrogen for use in other biofuels plant or for the conversion of CO2 stream to biofuels or renewable fuels, depending on the source of the CO2.

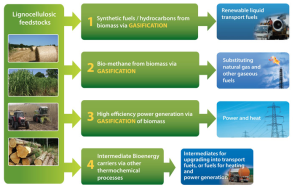

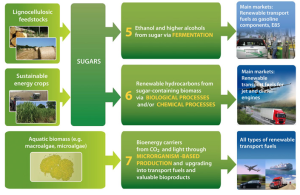

Both thermochemical and biochemical conversion routes will be deployed in the coming decade to produce biofuels directly such as ethanol, methanol and FT-diesel. Also, thermochemically-produced intermediates such as bio-oils will be produced by processes like pyrolysis and, regarding high-moisture content feedstocks, by hydrothermal liquefaction. Such intermediates will predominantly be converted to drop-in biofuels by refinery-like processes, either as an integrated biofuel value chain or as a co-feed to a fossil refinery value chain. Key innovations on bioenergy for the next 10 years are expected to occur C both by evolution of technologies now being demonstrated or piloted and by development of new technologies that will in some years possibly reach such a stage. Some recent technological progress on bioenergy and biofuels are described in the next sections, aligned with European Technological and Innovation Platform on Bioenergy (ETIP-Bioenergy) current value chains for advanced biofuels and heat and power (Fig. 1).

Improving current bioenergy: from 1st to 4th value chain by means of gasification and thermochemical processes

The gasification technologies, i.e. where the dried biomass feed is converted to a gas at temperatures of 800-1,500°C at pressures between 0.1 and 4 MPa, have had difficulties to come to the first industrial plants, e.g. the large projects (100-200 MW of products) proposed in the EU as a part of the NER 300 program despite several pilot developments have been or are operated. Instead, there are some more modest capacity plants in operation commissioning.

The GoBiGas plant in Gothenburg with an output of 20 MW biomethane based on a Topsoe process, has recently reached its nominal capacity after debottlenecking the gas cleaning trains. It has also succeeded in raising the longest uninterrupted run from around 1,500 hours on several occasions to 1,800 hours. Unfortunately, the plant will be soon mothballed because of economic reasons.

Other developments in the production of bio-methane by the gasification route is the 4-MW plant from GoGreenGas, now under construction in the UK. This plant is an industrial demonstration for the APP plasma gasification technology using RDF as the fuel, the gas being fed to the AMEC Foster Wheeler VESTA methanation.

There is also a planned industrial project in the Netherlands, Ambigo, featuring the Milena gasification, OLGA tar removal and ESME membrane synthesis processes, and where the final investment decision is pending. This project will have a capacity of 4 MW of bio-methane too.

The Enerkem RDF gasification plant in Edmonton Canada has had the last methanol-to ethanol stage installed in 2017 and can now produce 38,000 m3 of ethanol or an equivalent volume as methanol. A study is being made with i.a. Akzo Nobel for a plant with over five times the above capacity for the port of Rotterdam.

In addition, the RDF Fulcrum Bioenergy plant in Nevada and Red Rock Biofuels woody biomass plant in Oregon both were successful in securing financing during late 2017, after the Department of Defense funding in 2014. These plants will be producing 40 million litres and 57 million litres, respectively, of dropin hydrocarbon biofuels via the FT process.

Concerning pyrolysis technology, i.e. the conversion of biomass to pyrolysis oil, char and gases at 450-550 °C, the Fortum plant at Joensuu and the Empyro plant in the Netherlands both have started operation. These oils are primarily used as substitutes for fuel oil, but there has been a limited number of pilot scale tests of the upgrading of such oils to drop-in biofuels. Current developments are related to hydrocatalytic and catalytic pyrolysis at pilot scale to obtain a bio-oil intermediate with less oxygen than by the conventional fast pyrolysis process.

In recent years, hydrothermal liquefaction (HTL), which is a technology operating at 250-350 °C and pressures high enough to maintain the solvent, mostly water, in liquid phase (20-35 MPa), has advanced. A demo plant is being planned in Norway by Silva Green Fuels and in Canada by Canfor using forest and pulping residues by means of the Steeper and Licella technologies, respectively.

As far as it concerns electricity production, nowadays there are numerous installations to produce power and heat from biomass at a small scale (e.g. 0.01-5 MWe). These plants use gasifiers in combination with internal combustion engines at efficiencies higher than obtained from steam cycles at a comparable scale. Higher power efficiency approaching larger power plants requires that state-of-the-art gas engines is replaced with fuels cells or some other innovations.

However, the heat being generated need to be utilized to obtain a high total efficiency. The integration of biomass gasification with biogas or solar and wind power (RES-Hybrids) offers interesting alternatives for production of renewable energy at farm and village scale, in both rural and agricultural areas of Europe. Gasification followed by various forms of gas cleaning can also be applied to generate clean gaseous fuels from low-grade fuels such as different wastes and straw. Removing gas contaminants prior to combustion either minimizes corrosion and deposition in boilers or makes the gas more suitable for industrial furnaces. The commercialization of gasification systems for larger scale power generation has been slow and promising technologies, such as biomass integrated gasification combined cycle (IGCC), have not found their way to the market.

The biological and chemical approach

These three biomass value chains comprise a range of biological/ biochemical based technologies towards production of alcohols, hydrocarbons or fatty acids from biomass, both lignocellulosic or aquatic biomass (e.g., algae). The value chain of cellulosic ethanol production implies fractionation and hydrolysis of the biomass to sugars and lignin, followed by the fermentation of the sugars to ethanol. This technique is being used in a handful of plants (Biochemtex, Poet/ DSM, Raízen, GranBio, etc.) at industrial scale (40-110 million liters per year), but also other developers are trying to come to this milestone.

Such first industrial plants, having solved some technological problems associated with e.g. biomass feeding and pre-treatment, are paving the way to reach an industrially mature biochemical value chain for wider deployment. However, in addition to technical issues and low energy prices, some of the first-of-its-kind plants have also been subject to collateral damage from financial problems or strategic changes in the parent entities (e.g., M&G group- Biochemtex, DuPont, Abengoa).

The production of higher alcohols, e.g., iso-butanol or butanol, has advantages over ethanol. Their energy content is higher than that of ethanol and closer to that of gasoline and, more importantly, it has no compatibility, miscibility or material problems. The US company Gevo Inc., was the first investor to build a pilot machinery for iso-butanol plant at Luverne, Minnesota, USA using a recombinant yeast strain.

Butamax, which is a joint venture between BP and Dupont, have also developed a similar technology at pilot scale in the UK. Some technologies developed to convert alcohols to hydrocarbons have reached pilot scale and this conversion pathway has overall won acceptance for hydrocarbons production for blending into jet fuel.

Moving from the ethanol or higher alcohols value chain to hydrocarbons via biological pathways, Global Bioenergies is the only European-based company that has a fermentation process for converting sucrose directly into hydrocarbons. It is currently operating a 100 tonnes per year demonstration plant in Dresden (Germany) after successfully developed its engineered yeast strain in a pilot plant in France.

Their objective is to operate a bio-isobutene plant of 50,000 tonnes in 2018. Isobutene is a key compound for ETBE production and up to now it has been only available from fossil origin. It can also be chemically converted in isooctane and isododecane, which are gasoline additives too. Global Bioenergies have already produced a significant batch sample of such fuels for testing by Audi.

Outside of Europe, other biochemical pathways for the sugarto- hydrocarbon pathways are being pursued. DSM has a production plant in Brazil, formerly owned by Amyris, where farnesene can be produced among a range of other non-fuel products. This component can be blended into jet fuel at a rate of 10% after hydrogenation to farnesane. However, Amyris technology is still based on sugars from crops (e.g., sugarcane) and it has not been not tested on lignocellulosic sugars yet.

The last value chain to address here is the use of light and CO2 for production of energy carriers and upgrading them for biofuels. In spite of intense effort in R&D in algae in recent years, the development and the transition to the desired scale of demonstration have not been so accelerated as expected in Europe and worldwide. The main EU microalgae for energy project is the ALL-GAS project, located in Southern Spain (Chiclana de la Frontera). The Prototype plant is in continuous operation since September 2014. It comprises 1,000 m2 cultivation area plus around 200 m2 downstream processes such as harvesting, anaerobic digesters, biogas upgrading, dewatering and biomass boiler. The Demo plant, which has almost 3 hectares of microalgae cultivation, started the operation in 2017. It aims at demonstrating sustainable biomethane production from microalgae biomass grown on wastewaters fed into open raceways ponds at large scale.

Concerning the use of algae for sugar (macroalgae) or oil (microalgae) production, only the latter one has some pilot facilities in EU (e.g., Buggypower, Porto Santo; Camporosso, Italy) but none of them is actively focused on bioenergy. To date, the number of demonstration facilities to produce bioenergy vectors from micro and macro-algae, solar radiation and CO2 as well as for upgrading biofuels for carrier sector use is limited worldwide and the available data are scarce.

Other technologies in development

The rapid build-up of RE power capacity and the associated reduction in cost has generated an interest for using energy to produce hydrogen from electrolysis. Such component can later be used as a bio-fuel, as a co-feedstock in the production of other biofuels by thermochemical pathways or for chemical conversion of e.g. alcohols of lipids or even to recycle CO2 captured from industrial process by conversion to fuels like methane or methanol. The latter technology, named power-to-gas or power-toliquids (PtG, PtL) is being tested at pilot scale.

Many technological options for novel biofuels are being studied at laboratory scale. One interesting and challenging technology is to harness solar energy by biosolar cell factories (BSCF). By this technique, phototrophic microorganisms (e.g. cyanobacteria, eukaryotic algae) directly catalyze the conversion of CO2 and H2O into oxygen and chemical energy (e.g., fuel) in a CO2-neutral way and they bypass the production of a biomass intermediate. Another approach for the future is the use of extremophiles microorganisms that could be engineered as bio-solar cell factories, since their ability to grow at extreme conditions (high temperature, high saline, high/low pH values) minimizes the risk of microbial contaminations at open ponds as well as in closed unsterile photobioreactors.

Direct solar energy can also be utilized in many alternative ways to provide the required process heat for thermochemical conversion processes. These systems were studied and evaluated in detail already in the 1980s, but only now interesting applications are reported in development of renewable fuels from solar energy. Such implementations reach an energy conversion efficiency of 18%, defined as the ratio of the heating value of the syngas being produced to the solar radiative energy input and the heating value of the feedstock.

The cost-benefit analysis as a key feature to bioenergy development

As indicated above, there is a variety of technologies utilizing biomass to produce bio-fuels and other energy carriers, and which are at different technology readiness levels. However, while promising R&D at laboratory scale can often reach validation or pilot stage rather easily, it becomes increasingly difficult and time-consuming to reach the demonstration phase and first industrial plant. Often, main barriers to take-up of new high-efficiency technologies have been of an economic nature.

There is therefore a strong need to continue to support demonstration activities to come to industrial scale. Especially the balance between risk and benefits of the first demonstration and flagship plants is very challenging. Despite long-term incentives such as feed-in-tariffs, tradable certificates or carbon taxation etc., there is the necessity to go from flagships to a wider deployment. The main cost drivers in biofuel and bioenergy conversion systems are the feedstock cost and the capital related cost, while the main benefit is the GHG reduction. Since, overall, biomass resources are limited, optimization calls for allowing the use of a variety of feedstocks including low cost, low quality materials in cost-efficient plants. This becomes a trade-off between the cost of the installation and the biomass conversion efficiency together with the greenhouse-gas.

There is therefore a need for a market mechanism to prioritize the importance of GHG savings to compensate for the most often higher cost of biofuels relative to fossil fuels. But, in this context one should also acknowledge that there are also other and wider benefits and creating income for all the stakeholders of the entire value chain from field or forest to ready-for-use fuels.

This article is by Lars Waldheim, Waldheim Consulting, Chair of WG2-Conversion of ETIP-Bioenergy, and Francisco Gírio, LNEG, Bioenergy Unit, Vice-Chair of WG2-Conversion of ETIP-Bioenergy.